A Step-by-Step Guide to Using Pipe Pushing Rollers Safely and Effectively

- infospmequipment

- Feb 7, 2024

- 7 min read

Updated: Mar 29, 2024

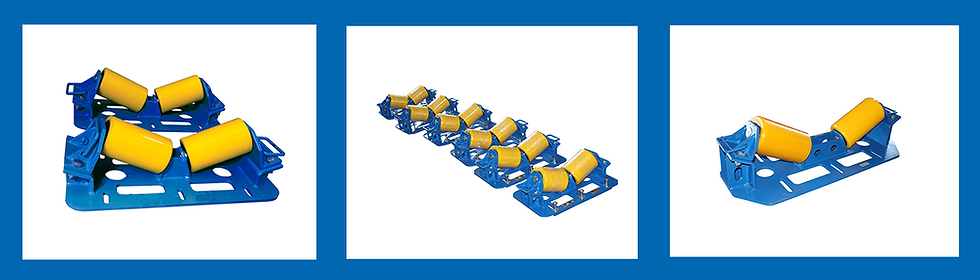

SPM Equipment Pipe Pushing Roller is a high-quality, specialized, and efficient solution for pipe handling needs in a wide range of industries. With its unique pipe pushing feature, adjustable height, and durable construction, it provides a safe and effective way to handle pipes of various sizes and weights.

Introduction

Welcome to our guide on using pipe pushing rollers safely and effectively! Whether you’re a seasoned professional or tackling a project for the first time, understanding the proper use of this equipment is crucial.

Pipe pushing rollers are essential tools in various industries, including construction and plumbing, to efficiently install pipelines. This guide will walk you through each step of the process, ensuring you have the knowledge to use these tools safely while maximizing productivity. Let’s get started!

Our pipe rollers have been extremely sturdy and resilient. Their rugged qualities and ease of use make them an ideal fit for directional drilling applications and they are often found in oil and gas pipeline equipment projects. Our pipe roller presence greatly reduces require manpower and operational time.

Understanding Pipe Pushing Rollers

What are pipe pushing rollers?

Pipe pushing rollers are specialized tools designed to safely and efficiently maneuver heavy pipes into position for installation or welding. These rollers are mounted on sturdy frames and feature rotating wheels or bearings that cradle the pipe, allowing it to roll smoothly along the desired path. The design minimizes friction and facilitates the movement of pipes over a variety of surfaces, making them invaluable in construction and pipeline industries.

Importance and benefits of using pipe pushing rollers

Using pipe pushing rollers brings a host of advantages. Firstly, they significantly reduce the physical strain on workers, minimizing the risk of injury from lifting or pushing heavy pipes manually. This also translates into improved productivity, as pipes can be moved faster and with less effort. Additionally, pipe pushing rollers protect the integrity of the pipes by preventing scraping and damage that can occur when dragging pipes across rough surfaces. Their use ensures that pipes are installed more efficiently, safely, and with a higher degree of precision.

Preparing for the Job

Checking the condition of the rollers

Before beginning any project, it's crucial to inspect the condition of your pipe pushing rollers. Look for signs of wear and tear, such as cracks, rust, or damage to the rollers and frame. Ensure that all moving parts are well-lubricated and rotate freely without resistance. Check for any loose bolts or components that may compromise the stability of the unit. If any defects are found, it's vital to repair or replace the affected parts before proceeding with the job.

Assessing the work area for potential hazards

Safety starts with a thorough assessment of the work area. Look for uneven terrain, obstacles, or slippery conditions that could impede the movement of the pipe pushing rollers or pose a risk to workers. Identify any overhead hazards, such as power lines, and ensure that the route is clear of debris. Consider the overall layout of the site and plan the most efficient and safest path for moving the pipes. Taking the time to assess and prepare the environment can prevent accidents and streamline the installation process.

Gathering the necessary tools and equipment

Having the right tools and equipment on hand is essential for a smooth operation. In addition to the pipe pushing rollers, you'll need safety gear for all workers, including gloves, hard hats, and steel-toed boots. Ensure you have tools for securing the pipes to the rollers, if necessary, and any other items required for the particular job, such as tape measures, leveling tools, and markers for pipe alignment. Organizing and preparing your tools in advance can significantly reduce downtime and enhance job efficiency.

Safety Tips for Using Pipe Pushing Rollers

The Beam Clamp Rigging Roller allows for safe and efficient transport and positioning of large and heavy structural components, reducing the risk of injury to workers and minimizing the need for manual lifting and handling.

our customers by manufacturing and Supplying high-quality Oil and Gas pipeline equipment all over the world. About our Offered products range consists of CS Pipe Welding Equipment, DSS Welding Equipment with Purge Chamber , Pipe Lowering & Lifting Equipment, Pipe Roller & Rotator, Pipe Bending Equipment, Pipe Cutting & Line Pipe Plant Equipment, Pipe Coating Equipment and Oil and Gas Pipeline Construction Equipment.

Wearing appropriate personal protective equipment

Before diving into the task at hand, the first step in ensuring safety is to don the right personal protective equipment (PPE). This includes wearing safety helmets, gloves, and eye protection. What you wear can be a major factor in preventing injuries, especially in an environment where heavy equipment like pipe pushing rollers are in use. It's essential not just to have these items but to make sure they fit properly and are in good condition.

Ensuring proper training and certification

Using pipe pushing rollers isn't something to improvise. It's crucial that everyone involved in the operation has undergone appropriate training and holds any necessary certifications. This ensures all team members are knowledgeable about the equipment's operation, understand safety procedures, and can identify risks. It's about making sure the job is not just done, but done safely and efficiently.

Communicating effectively with the team

Efficient communication is the backbone of safety and success in operations involving heavy equipment. Whether it's signaling when to start the push or alerting the team about a potential hazard, clear and concise communication can prevent accidents. Using walkie-talkies or hand signals are effective ways to maintain this communication, especially in noisy environments.

Maintaining good body mechanics while operating the rollers

Good posture and body mechanics are often overlooked but are essential in avoiding strain and injury. When operating or adjusting pipe pushing rollers, it’s important to use your legs rather than your back to lift, keep heavy loads close to your waist, and avoid twisting movements by positioning your feet in the direction you're moving.

Step-by-Step Guide to Using Pipe Pushing Rollers

Step 1: Positioning the rollers

Start by positioning the rollers securely on a stable surface to ensure they are in the correct place for the pipe's entry. Check that the rollers are aligned with the path the pipe will take to ensure a smooth operation.

Step 2: Aligning the pipes

Carefully align the pipes with the center of the rollers. Proper alignment is crucial as it affects the effectiveness of the pushing operation and helps prevent damage to both the pipes and the rollers.

Step 3: Adjusting the roller pressure

Adjust the pressure exerted by the rollers to match the size and weight of the pipe. This ensures the pipe moves smoothly without being damaged or becoming stuck.

Step 4: Activating the rollers

Once everything is in place and double-checked, activate the rollers. Start at a lower speed to ensure everything is functioning as expected before gradually increasing to the operational speed.

Step 5: Guiding and monitoring the push

As the pipe moves, guide it to ensure it stays aligned and monitors the process closely. Be prepared to adjust the speed or alignment as necessary.

Step 6: Identifying and resolving obstacles

Keep an eye out for and address any obstacles or issues that arise during the push. This might include realigning the pipe, adjusting the rollers, or even stopping the process if needed to ensure everything continues smoothly.

Step 7: Monitoring the progress

Throughout the operation, continuously monitor the progress of the pipe pushing. Ensure the pipe is moving at the intended speed and that there are no issues with the equipment or the pipe itself. Adjust the roller pressure and alignment as needed until the task is complete.

Troubleshooting

Pipe pushing rollers, vital tools for efficiently moving and installing pipelines, occasionally encounter issues that can impede progress. Identifying these common problems is the first step toward ensuring a smooth operation.

Common issues encountered when using pipe pushing rollers

When using pipe pushing rollers, several issues may arise, including:

Rollers becoming stuck or not turning smoothly.- Misalignment of the pipe, causing uneven pressure or potential damage to the pipe.- Excessive wear on the rollers, leading to decreased efficiency and potential failure.- Noise or vibration indicating a possible malfunction inside the roller mechanism.

Recognizing these signs early can prevent more significant problems down the line.

How to troubleshoot and overcome these issues

Troubleshooting problems with pipe pushing rollers involves a few straightforward steps:

Ensure that all rollers are clean and free from debris. Dirt or small objects can obstruct the roller movement.- Check for proper alignment of the rollers themselves as well as the pipe on the rollers. Misalignment can cause uneven wear or damage.- Inspect for wear and tear. If a roller shows significant wear, it may need replacement to ensure smooth operation.- If there's unusual noise or vibration, inspect the internal mechanism of the rollers for loose parts or signs of damage.

By regularly troubleshooting your pipe pushing rollers, you can keep your project on track and minimize downtime.

Maintenance and Care of Pipe Pushing Rollers

Proper maintenance and care are essential for extending the life of pipe pushing rollers and ensuring their safety and effectiveness.

Cleaning the rollers after use

Cleaning is a critical step in maintaining pipe pushing rollers. After each use:

Wipe down the rollers to remove any dirt, mud, or grime.- Use a mild detergent and water if necessary, but make sure to dry the rollers thoroughly to prevent rusting.- Check for any lodged debris between components and remove it.

This simple step can drastically increase the lifespan of your equipment.

Inspecting for damages and wear

Regular inspection is vital to identify early signs of damage or wear:

Look for any cracks, dents, or deformities on the rollers and the frame.- Check bearings and moving parts for signs of wear or damage.- Pay attention to the surface of the rollers to ensure they are smooth and free of any defects that could damage the pipe.

Addressing these issues promptly can prevent more severe problems and potential failures during operation.

Lubricating and storing the rollers properly

To keep your pipe pushing rollers operating smoothly:

Lubricate all moving parts regularly according to the manufacturer's recommendations. This reduces friction, wear, and the risk of seizing.- Store the rollers in a dry, covered location to prevent rust and corrosion.- If possible, refrain from stacking heavy objects on the rollers during storage to avoid warping or other damage.

By adhering to these maintenance and care guidelines, you ensure the longevity and reliability of your pipe pushing rollers, supporting safe and efficient pipeline installation and maintenance projects.

Conclusion

As we wrap up this guide on using pipe pushing rollers, remember that the key to success lies in preparation, proper techniques, and safety. By following the steps outlined, you ensure not only the effectiveness of your work but also the safety of everyone involved. Always consult the manufacturer's guidelines, wear appropriate safety gear, and never underestimate the importance of regular equipment checks. With these practices in mind, you're well on your way to mastering the use of pipe pushing rollers.

Comments